The Super Visa is a multi-entry visa allowing parents and grandparents to visit Canada for up to two years. It simplifies family reunification with extended stay options.

1.1 What is the Super Visa?

The Super Visa is a multi-entry visa designed for parents and grandparents of Canadian citizens or permanent residents. It allows extended stays in Canada for up to two years, with the option to renew. Applicants must meet specific requirements, including a medical examination and providing proof of financial support. The Super Visa application form PDF is a key document in the process, outlining necessary details for a successful submission. It ensures families can reunite while adhering to Canada’s immigration regulations.

The Super Visa Program aims to reunite families by enabling parents and grandparents to visit Canada for extended periods. It offers a streamlined process with multi-entry benefits, allowing stays up to two years. The program ensures that applicants meet health and financial standards while facilitating family bonds. The Super Visa application form PDF is central to this process, providing detailed guidelines to ensure compliance with Canadian immigration requirements and policies. This initiative supports the well-being of families while maintaining immigration integrity. The Super Visa requires applicants to meet specific criteria, including being a parent or grandparent of a Canadian citizen or PR. Financial and medical standards must be met. The Super Visa is designed for parents and grandparents of Canadian citizens or permanent residents. Applicants must demonstrate they are the biological or adoptive parents/grandparents of the sponsor. The application form PDF requires detailed personal and family information. Applicants must also meet financial, health, and other eligibility criteria to qualify. The process ensures family reunification while maintaining Canada’s immigration standards. To qualify for the Super Visa, applicants must meet specific financial requirements. The sponsor in Canada must provide proof of income through an invitation letter. Applicants must also submit proof of their financial stability. This includes bank statements, employment letters, or other documents showing sufficient funds to support their stay in Canada. The financial assessment ensures applicants can maintain themselves without relying on Canadian public funds. This step is crucial for a successful application. Applicants for the Super Visa must undergo a mandatory medical examination. This exam ensures the applicant does not pose a health risk to Canadians. The medical assessment includes standard tests and evaluations. A designated medical practitioner approved by Immigration, Refugees and Citizenship Canada must conduct the exam. The results are valid for 12 months and must be submitted with the application. This step is critical to meet health requirements for entry into Canada. The Super Visa application process involves submitting a complete application with required documents. The process ensures a streamlined experience for parents and grandparents to visit Canada. To apply for the Super Visa, download the application form PDF from the official website. Fill it accurately, gather required documents, and submit the complete package. Ensure all details are correct to avoid delays. A PDF reader is necessary for accessing and completing the form. Follow the instructions carefully and double-check the submission requirements before finalizing. Proper preparation ensures a smooth and successful application process. Applicants must submit a completed Super Visa application form PDF, proof of financial support, medical exam results, and travel medical insurance. A letter of invitation from the Canadian host is also required. Ensure all documents are accurate and up-to-date to meet eligibility criteria. Proper documentation is essential for a smooth application process and to avoid delays or rejection. Organize the documents as per the checklist provided by the visa office. Attention to detail is crucial for approval. Download the official Super Visa application form PDF from the Canadian government website. Open it using Adobe Acrobat and fill in personal details, travel plans, and sponsor information. Ensure all fields are completed accurately. Sign the form electronically and save a copy. Attach the PDF to your online application or print it for submission. Use the “Snapshot” tool for clear photocopies of documents. Accuracy is key to avoid delays or rejection. The Super Visa application form PDF can be submitted online or via mail. For online submission, fill the form, attach required documents, and submit through the official portal. For physical submission, print the completed PDF, sign it, and mail or submit in person at a Visa Application Center. Ensure all details are correct and documents are complete to avoid delays. Check the official government website for the most current submission guidelines. A mandatory medical exam ensures applicants meet health standards for the Super Visa. The exam is conducted by approved physicians and includes basic health checks. The medical exam is crucial for the Super Visa as it ensures applicants meet Canada’s health standards. It checks for potential health risks and ability to access care. This step helps prevent burdens on the healthcare system and ensures public safety. A clean bill of health is essential for a successful application. The exam must be conducted by an approved physician and includes basic health checks. It is a mandatory step to validate the visa application process. To schedule a medical exam for the Super Visa, applicants must use an approved physician. After submitting the application, the visa office provides forms and instructions. These documents must be taken to the exam. The exam assesses health status to ensure it meets Canadian standards. It’s a mandatory step, and only approved doctors can conduct it. Applicants should contact designated medical professionals in their area to book an appointment promptly. Proper documentation is essential for a smooth process. During the medical exam, applicants undergo standard procedures, including blood pressure, weight, and height checks. Blood and urine tests may be conducted. A review of medical history and vaccination status is also part of the process. The exam ensures the applicant meets Canada’s health requirements. It’s thorough to assess any potential health risks. Applicants should bring all medical records and be prepared to answer detailed health-related questions. The exam is a critical step in the Super Visa application process. Super Visa processing times vary based on application completeness and visa office workload. Applicants should check official sources for the latest updates and expectations. The average processing time for Super Visa applications varies, typically ranging from a few weeks to several months. Processing times depend on the completeness of the application and the workload of the visa office. Applicants are advised to check official government sources for the most up-to-date information to plan accordingly. Ensuring all required documents are submitted correctly can help expedite the process. The processing time for Super Visa applications can vary due to several factors. These include the completeness of the application, the workload of the visa office, and the speed of providing additional information if requested. Applications with missing or incorrect documents may experience delays. Additionally, the time taken for medical examinations and police certificates can influence overall processing. Applicants are encouraged to submit their applications well in advance and monitor official updates for the latest processing trends. Super Visa applicants must have valid medical insurance covering at least $100,000 for the duration of their stay in Canada. The insurance must be purchased from a Canadian provider and be valid for multiple entries. This ensures that any unexpected medical expenses are covered, making it a mandatory requirement for the application process. Insurance is mandatory for the Super Visa to ensure applicants have coverage for medical emergencies, protecting both the individual and Canadian healthcare systems. The policy must cover at least $100,000 for the duration of their stay, including multiple entries. This requirement ensures that visitors can access necessary healthcare without financial strain, safeguarding public health and reducing the burden on Canada’s medical services. It is a critical component of the application process. To purchase Super Visa insurance, applicants can select a Canadian insurance provider. They must download the Super Visa Insurance Application form, fill it out, and submit it along with required documents. The policy must cover at least $100,000 for medical emergencies. Once approved, the insurance document is issued and must be submitted with the visa application. This step is crucial for completing the visa process successfully. Common rejections include incomplete or incorrect applications, failure to meet financial requirements, and medical inadmissibility, highlighting the need for accurate and complete submissions. An incomplete or incorrect application is a leading cause of Super Visa rejections. Errors in forms, missing documents, or failure to follow instructions can delay or deny the process. Ensure all fields are accurately filled, required documents are attached, and guidelines are strictly followed. Double-checking the application before submission is crucial to avoid such issues and improve approval chances. Failure to meet financial requirements is another common reason for Super Visa rejection. Applicants must provide proof of their financial stability, such as bank statements or employment letters, to demonstrate they can support their stay in Canada. The income must meet or exceed the minimum necessary income (MNI) required by Canadian immigration standards. Ensuring all financial documents are accurate and up-to-date is essential to avoid rejection and ensure a smooth application process. Medical inadmissibility is a significant reason for Super Visa rejection. Applicants must undergo a medical examination to ensure they do not pose a health risk or excessive demand on Canada’s healthcare system. The exam assesses conditions that could endanger public health or increase healthcare costs. Failure to meet medical requirements can result in visa denial. It is crucial to complete the exam honestly and provide accurate medical documentation to avoid rejection and ensure a successful application process. The Super Visa can be renewed or extended, allowing parents and grandparents to stay longer in Canada. Applicants must submit a new application or apply for extension before their current status expires to maintain legal stay. To renew the Super Visa, applicants must submit a new application, including required documents like proof of financial support and medical insurance. The process involves completing the application form, paying the fees, and submitting through the online portal or VFS. Ensure all documents are updated and meet current requirements. Processing times vary, so apply well in advance of the visa’s expiration to avoid status issues. To extend your stay in Canada under the Super Visa, you must submit an application for a visitor record extension before your current status expires. This process involves completing the IMM 0008 form and providing updated documents, such as proof of financial support and valid medical insurance. Ensure all information is accurate and submitted on time to maintain legal status. The extension allows continued residence without leaving the country. Timely application is crucial to avoid complications. You can check the status of your Super Visa application online through the official government portal or by contacting the visa office directly for updates. The online tracking system allows applicants to monitor their Super Visa application status in real-time. By visiting the official government portal, you can log in using your application number and personal details to view updates. This service provides transparency and convenience, ensuring you stay informed about the progress of your application. Regularly checking the portal helps you stay updated and take necessary actions if required. Always ensure your internet connection is secure when accessing this service. Applicants can contact the visa office for updates on their Super Visa application. This can be done via email, phone, or through the official government website’s web form. Ensure to provide your application number and personal details for efficient processing. The visa office will only respond to inquiries related to the status of your application. It is recommended to wait for the standard processing time before reaching out for updates. Always use official channels to avoid delays. The Super Visa simplifies family reunification, offering extended stays for parents and grandparents. Ensure proper preparation and seek professional advice for a smooth application process. Ensure all documents are complete and accurate, including the Super Visa application form PDF. Double-check financial and medical requirements. Purchase mandatory insurance covering the entire stay. Attend the medical exam as instructed and follow submission guidelines carefully. Avoid delays by applying well in advance. Use online resources or consult professionals for assistance. Proper preparation and attention to detail will significantly improve your chances of approval.1.2 Purpose of the Super Visa Program

Eligibility Criteria for the Super Visa

2.1 Who Can Apply for the Super Visa?

2.2 Financial Requirements for Applicants

2.3 Medical Examination Requirements

Super Visa Application Process

3.1 Steps to Apply for the Super Visa

3.2 Required Documents for the Application

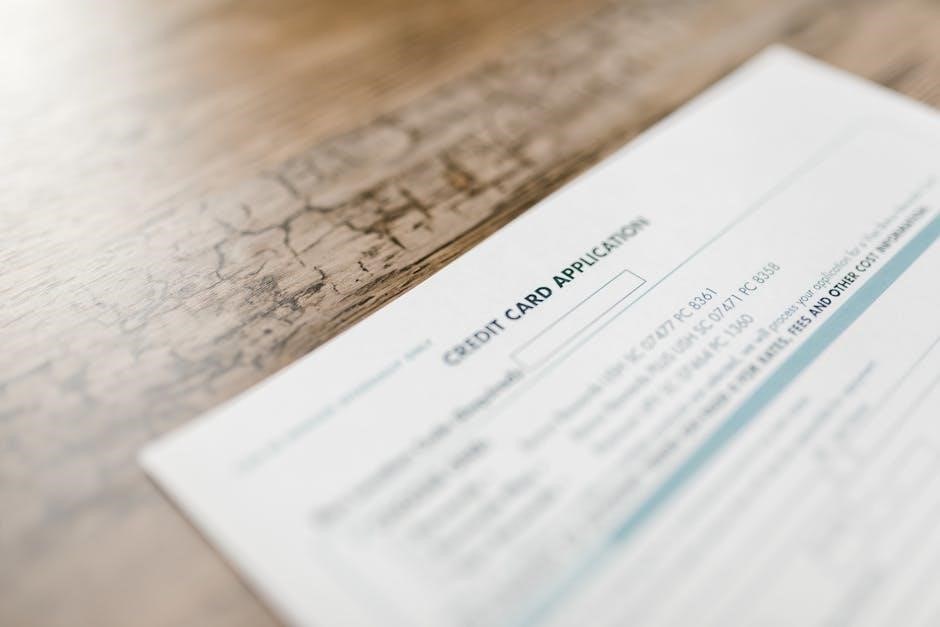

3.3 How to Fill Out the Super Visa Application Form PDF

3.4 Submission Methods for the Application

Medical Examination for Super Visa

4.1 Importance of the Medical Exam

4.2 How to Schedule a Medical Exam

4.3 What to Expect During the Medical Exam

Super Visa Processing Times

5.1 Average Processing Time for Super Visa Applications

5.2 Factors Affecting Processing Time

Super Visa Insurance Requirements

6.1 Why Insurance is Mandatory

6.2 How to Purchase Super Visa Insurance

Common Reasons for Super Visa Rejection

7.1 Incomplete or Incorrect Application

7.2 Failure to Meet Financial Requirements

7.3 Medical Inadmissibility

Renewing or Extending the Super Visa

8.1 How to Renew the Super Visa

8.2 Extending Stay in Canada

Checking the Status of Your Super Visa Application

9.1 Online Tracking of Application Status

9.2 Contacting the Visa Office for Updates

10.1 Final Tips for a Successful Super Visa Application